How can I prevent the power cord from causing voltage fluctuations?

When a step-down regulator or linear regulator power supply is used, the voltage is generally regulated to a set value to supply the load. In some applications (e.g., laboratory power supplies or electronic systems where long cables are used to connect various components), it is not possible to ensure that an accurate regulated voltage is always available at the desired point of location because of the various voltage drops on the interconnecting wires. Control accuracy depends on a number of parameters, one being the DC voltage accuracy when the load requires a continuous constant current, and the other being the AC accuracy of the generated voltage, which depends on how the generated voltage varies with load transients. (from easybom ) Factors affecting DC voltage accuracy include the required reference voltage (which may be a resistive voltage divider), the behavior of the error amplifier, and a number of other influences on the power supply. Key factors affecting the accuracy of the AC voltage include the selected power level, the backup capacity, and the architecture and design of the control loop.

However, in addition to all of these factors that can affect the accuracy of the generated supply voltage, other influences must also be considered. If the power supply is spatially separated from the load it is required to power, there will be a voltage drop between the regulated voltage and the location where power is needed. This voltage drop depends on the resistance between the regulator and the load. It may be a cable with plug contacts or a longer alignment on the circuit boards.

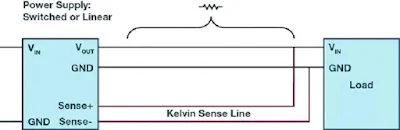

Figure 1 shows that there is resistance between the power supply and the load. The voltage loss across this resistance can be compensated for by slightly increasing the voltage generated by the power supply. Unfortunately, the voltage drop generated across the line depends on the resistance load current, i.e., the current flowing through the line. Higher currents result in higher voltage drops compared to lower currents. As a result, the load is supplied by a regulation voltage with rather low accuracy, which depends on the line resistance and the corresponding current.

| |

| Fig. 1. Physical distance between the regulator and the load in question. |

A solution to this problem has long been available in the form of an additional pair of connections in parallel with the actual connecting line, using a Kelvin detection line to measure the voltage on the side of the electronic load. In Figure 1, these additional lines are shown in red. These measurements are then integrated into the supply voltage control on the power supply side. This approach is effective but has the disadvantage of requiring additional detection leads. As there is no need to carry high currents, the diameters of such leads are usually very small. However, having measuring leads in the connecting cables for higher currents entails additional work and higher costs.

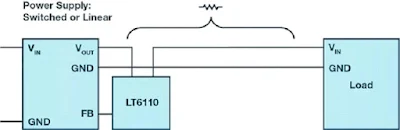

Voltage drops on the connection line between the power supply and the load can be compensated for without the need for an additional pair of test leads. This is particularly relevant for applications where cable routing is complex and costly and where the resulting EMC interference can easily be coupled to the voltage test leads. The second option is to use a dedicated line voltage drop compensation IC such as the LT6110, which is inserted into the voltage generation side and measures the current before it enters the connection line. The output voltage of the power supply is then regulated according to the measured current, making it possible to regulate the load-side voltage very accurately, regardless of the load current.

| |

| Figure 2. Using the LT6110 to regulate the power supply output voltage to compensate for the voltage drop across the connection line. |

With a component such as the LT6110 , it is possible to regulate the power supply voltage according to the corresponding load current; however, such regulation requires information about the line resistance. Most applications will provide this information. If the connection line is replaced with a longer or shorter line during the life of the device, the voltage compensation realized with the LT6110 must also be adjusted accordingly. If the line resistance may change during device operation, a component such as the LT4180 can be used to provide a highly accurate voltage at the load side by making a virtual prediction of the connecting line resistance from an AC signal when the load side has input capacitance.

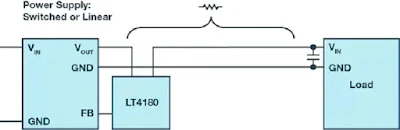

Figure 3 shows an application using the LT4180 where the resistance of the transmission line is unknown. The line input voltage is regulated according to the corresponding line resistance. With the LT4180, there is no need for a Kelvin-detected line; voltage regulation is achieved by gradually varying the line current and measuring the corresponding voltage change. The measurement results are used to determine the voltage loss in the unknown line. Optimal regulation of the DC/DC converter output voltage is achieved based on the voltage loss information.

| |

| Figure 3. Virtual remote measurement of a line using the LT4180 |

This measurement is effective as long as the nodes on the load side have low AC impedance. It is effective in many applications because loads behind long connection lines require a certain amount of energy storage. Due to the low impedance, it is possible to regulate the output current of the DC/DC converter and to determine the line resistance by measuring the voltage on the front side of the connection line. The ability to obtain a stable supply voltage is not only related to the voltage converter itself, but also to the load power line.

The required DC accuracy can be increased by additionally configuring the Kelvin detection line. In addition to this, integrated circuits can be used to compensate for voltage drops on the line without Kelvin detection lines. This option can be useful if the cost of Kelvin detection lines is too high or if existing lines must be used and no additional detection lines are available. Higher voltage accuracy can be easily achieved using these design techniques.

very useful article

ReplyDelete