The Use of Silk Screen Technology in Printed Circuit Board (PCB)

What is silk-screening?

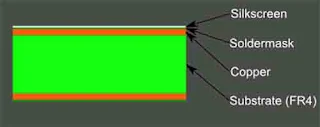

Silkscreen is a layer of ink traces used to identify components, test points, parts of the PCB, warning symbols, logos, and marks etc. This silkscreen is usually applied on the component side; however, using silkscreen on the solder side is also not uncommon. But this may increase the cost. Essentially a detailed PCB silkscreen can help both the manufacturer and the engineer to locate and identify all the components.

The ink is a non-conductive epoxy ink. The ink used for these markings is highly formulated. The standard colors we normally see are black, white and yellow. PCB software also uses standard fonts in silkscreen layers but you can choose other fonts from the system too. For traditional silk-screening you require a polyester screen stretched on aluminum frames, a laser photoplotter, spray developer and curing ovens.

Method of Silk-screening:

There are three basic ways to apply silkscreen.

1: Manual Screen-printing:

Manual screen-printing is done when the line widths are greater than 7 mil (0.007”) and the registration tolerance is 5 mil. For this method, you require a stencil of the text and traces made of nylon. The ink is pushed through the stencil onto the laminate. Next, the board is baked in a curing oven for the ink to cure. The application and set up is easy but the result is least precise.

2: Liquid Photo Imaging (LPI):

This method is used when the line widths are greater than 4 mil. Liquid Photo Imaging is quite similar to the process used for the application of solder mask. In this, a liquid photoimageable epoxy is coated on to the laminate and then exposed with UV light. After this, the board is developed and cured. It is much more accurate than manual screening

DLP is the most accurate of all these processes but is more expensive. In this process, an inkjet projector is used with acrylic ink that is applied to the raw PCB directly from the CAD data. The ink is cured with UV light as it is printed. It should be noted though that the acrylic ink does not cure on boards with silver finishes.

Importance of Silk-Screen:

A properly designed silk-screen can prove to be highly useful as it can reduce the chance of error and can reduce the time taken to spot the error. The silkscreen can easily label the passive components of the PCB no matter how packed the board may be.

There are a few things you should keep in mind regarding silk-screening. For example, the silkscreen epoxy should not be printed over pads or land PCBs that will be soldered as it will melt into the solder joint. This is why it should be applied over the solder mask. While designing you should keep the component outlines away from the pins (almost at a distance of 0.25 mm). Also you should check to see if the width of the silkscreen graphics is suitable to the design. Try to keep the line widths no less than 6 mil.

Knowing more about PCB and silk-screening can help you to reduce your PCB costs. For example, applying silk screen on only one side and choosing the standard colors will give you better overall pricing and give you the same benefits.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

This ARTICLE is Proudly Presented by PCBGOGO

Post a Comment for "The Use of Silk Screen Technology in Printed Circuit Board (PCB)"

Dont use outgoing links!